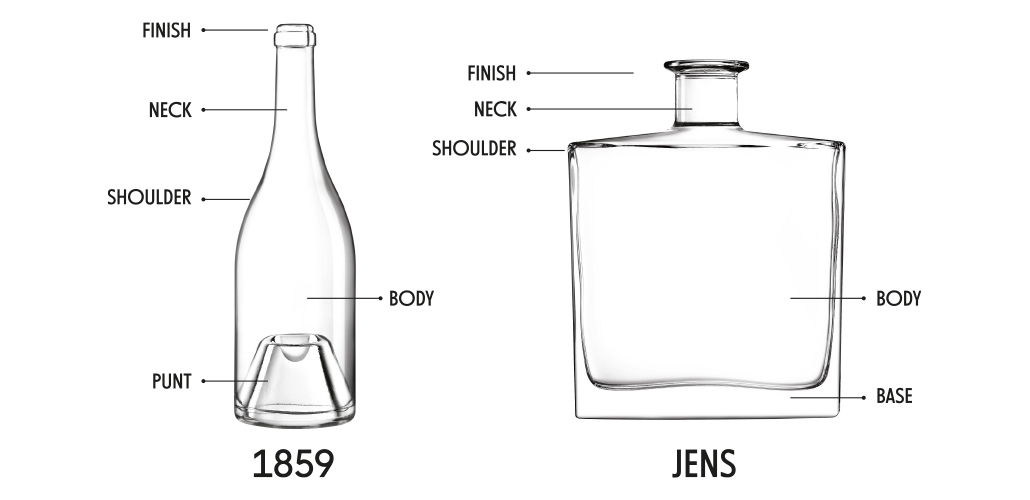

- Cartography of the bottle

- Embossing the finish

This solution consists in adapting a custom finish on a bottle model as long as it is technically compatible with the existing tooling. It can be a standardized finish, a special finish or even a finish personalized with an embossing wrapped around its periphery.

- Medallion embossing

This concept consists in positioning an embossing on the shoulder, using removable inserts. Offered in a selection of our “Wine” collection bottles, using this type of embossing can be economical in terms of development fees. This technique allows us to produce very detailed and perfectly reproducible embossings.

- Body / shoulder embossing

This concept consists in creating a set of custom finishing molds that are compatible with the existing blank molds from the catalog version. It allows for a personalization with embossed elements that can be positioned on the shoulder, the body or the lower body of the bottle.

- Lower body embossing

This concept consists in positioning a wrap-around embossing on the lower body of the bottle. The embossing can be the name of the winery, geometrical motifs, even figurative scenes...

- Base / punt embossing

This solution consists in developing custom base plates either just for the finishing molds or sometimes for both the blank and the finishing molds, in order to position the custom embossing on the base (in replacement of the usual knurling) or inside the punt.

- Complete tooling

Creating a complete tooling composed of blank and finishing molds is necessary when:

- a specific size is not available in the existing line,

- some of the dimensional characteristics are changed (height, diameter),

- the glass weight is significantly changed,

- the dimensions of the embossed finish are not compatible with the existing tooling.